|

|

|

|

|

|

|

2008 Blog (Read bottom up)

12/14/08

I let myself get talked into letting a professional build the door for my bench. I picked up the requisite wood at the local MacBeath and decided to have the wood finished out for me. It doesn't exactly come raw but it's pretty darn close, the cuts are wavy, they're not square, the wood is cupped.

I didn't worry about that too much for the drawers, and worked it as best I could, but the door is going to have multiple pieces and they need to fit well together. I figured "what the heck, I'll visit someone who has the right equipment and they can true it up." It's so much easier working with a finished piece of wood.

Anyway.... we get to talking and I describe what I'm doing, show him pictures from my I phone and he suggests a panel door with euro hinges. I hadn't thought of a panel door but they're easy to do so I figure, "why not". Then he says, "I can cut the groves for you and you can glue it together. I'll sell you the hinges too." Not wanting to sound ungrateful for the advice he was giving me and knowing it wouldn't really be any extra cost (his time is going to be spent working the wood into something that's usable) I said "sure".

Then I spent the rest of the day feeling it wouldn't be "my" bench if I had someone else route the groves for me. Every time someone asks me if I made the bench myself I'd have to say, "yes, but so and so routed the door for me". I guess I've got a pride of ownership thing going on and it sort of irks me. I like to do everything myself but it only makes sense since he's got all the equipment set up. It'll probably only take him 10 minutes and when he trues up the wood, he can do it with the door in mind.

Enough of my neurosis, when I got home yesterday I started turning reel seats. They're test seats really. I'm turning them from the Amboyna I picked up in March and I'm trying to figure out the process with the new lathe.

The initial turning went ok. I was able to round out the stock with my spur center but I must have applied too much pressure because my spinning center started oozing grease and seized up. Thinking it was toast, I used it as a center for my mandrel. The end of the mandrel was not cone shaped like I thought it was and ground up the tip of the spinning center. It started spinning again in the process.

I'd initially planned to use my long 5/16 drill but the mandrel I'm using turned out to be 7mm in diameter. I used a 1/4 bit yesterday and gave up. The bit is too short to drill all the way through the reel seat blank. I picked up a long boring bit from Home Depot this morning. It's long enough but too thin for its length. If I'm not careful, the bit tends to move off to the side. Next time around, Mr. Drill Bit needs to meet Mr. Dremel Tool for some attitude adjustment.

All and all though, things seem to be shaping up. I have some promising looking reel seat inserts.

12/12/08

Well, the knobs or "pulls" are on and are getting varnished.

If I can find some lumber for the door, I'll be all done.

I picked up some maple burl at Woodcraft today. I've pretty much settled on tulipwood and Amboyna for my seats but the piece of burl just looked too good.

12/07/08

I've started making the pulls for the bench. They'll be basic but functional.

The way things are going. I doubt I'll do any work on the Payne 198. I'll probably go straight to the FE Thomas. We'll see. I still need to order the ferrules for the FE Thomas and I suspect I won't be able to get them until the last week in February.

Saturday I attended a Christmas party with a bunch of local rod makers and aficionados. The rod makers in the Bay Area build to a very high level so it was great to be with so many great rod makers. I brought the 215 rod and let just about everyone cast it. The other rod makers liked the rod but all agreed that the butt was too heavy.

We did something that I hadn't done and that was to put a DT3 line on the rod. I like it with a WF4 and after casting it with a DT3 I suspect that my WF4 line is a little light. Most folks liked it with the DT3. I knew the butt was too heavy but now plan to bring it down quite a bit more than I had originally planned.

I was also encouraged to start hollow cutting my rods. Hollow cutting really is a west coast staple of rod making and I was told to "just do it." Once I get the solid built 215 taper to my liking, I'll start hollow cutting it. Perhaps I'll build hollow and solid version simultaneously.

I spent most of my day casting rods as I tend to do. I cast some really great rods. The craftsmanship of the rods from the rod makers present was humbling indeed. I looked the rods over as closely as I could. Most people who see me do this probably think I'm looking for flaws but it's just the opposite. I look for how good something can be so I can raise my own standard of rod making. I don't think it appropriate for me to mention the work of the rodmakers present but I was absolutely floored by what I saw. Floored and humbled. My own work has a long way to go but now I have a better idea what to look for/ strive for in my own work.

A fellow had one of Yukihiro Yoshida's rods. Yukihiro's rods have a very distinct action and this one was no different.

There was a Per Brandin quad that was outstanding! It was a 2wt if I recall correctly and was like casting air. It's amazing what one can do with cane in the hands of an extraordinary builder.

11/25/08

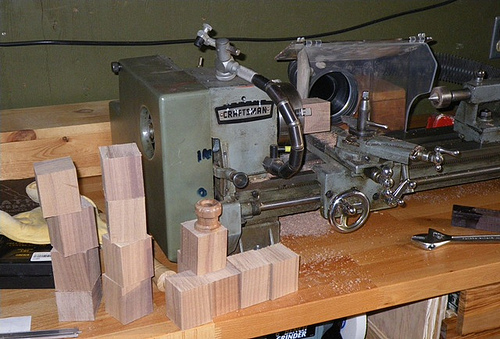

I've been spending my time working on the bench and accumulating tools for the lathe. My Craftsman lathe came very well equipped with just about everything one could need except bit holders and an expanding arbor. Most of the bits that came with the lathe are 1/2 inch bits and not 1/4 inch. It looks like the fellow who owned the lathe used the hold down post to hold the bits instead of using a bit holding tool. I picked up 5 bit holders and several 1/4 bits.

I also picked up an expanding arbor for making reel seat hardware. The arbor holds the nickel silver tubing. I got a screaming deal on ebay. 8 arbors of different sizes, the same arbors the big boys sell, for less than the price of one arbor at the various supply shops.

I've been doing a lot of work with the bench. It should be finished in a couple of weekends. I've decided on olivewood for the drawer faces. An expensive decision but one which I think will work out well. I've cut and fitted the drawer faces. I simply need to sand, finish and install them.

I've also bitten the bullet and decided to finish the bench top. This meant removing the two inner cabinets and removing the lathe (which was bolted on). I know, it sounds like a pain but after a stressful weekend of back to back to back 21 hour work days, it was nice to do something as simple as removing a few bolts, removing some drawers and lifting some boxes. I've already applied two layers of finish on the bench top. A home made brew of Varathane, mineral spirits and boiled linseed oil. It should make for a decent renewable finish.

11/10/08

I've been doing various and sundry things in the shop. I've split the cane for the second tip of the 3wt as well as the cane for the FE Thomas 3wt. The nodes are pressed and everything is straight so I simply need to rough the strips before planing.

I've also worked a little more on the bench. I'm debating whether or not to finish it. I'm pretty settled with things as they are, unfinished, but I keep thinking about what the top will look like in 5 years time. My other bench tops are protected by 1/4 inch MDF. It was such an ordeal to get the lathe set up, I really don't want to mess with it now. We'll see.

I've finally verified the Granger taper that I liked at the Gathering. Plugging it into my spreadsheet program it looks very similar to the 215 taper. No wonder I liked it.

11/02/08

I attended the Great Western Rod Makers gathering last weekend. I had a great time casting rods and fishing the upper sac. There were more rods than usual and I even had my 215 out for folks to cast. It wasn't a crowd favorite but plenty of folks seemed to like it. There were Paynes to cast, a Garrison 201 and several granger based tapers.

It's funny, I was thinking I didn't want to use the modified Powell grip but picking and casting the 215 was soooo comfortable. I spent the day casting rods with cigar grips but when I picked up the 215, it was like a breath of fresh air. I'm definitely going to stick with it.

There was an experiment with two rods, one flamed and one not. To tell the truth, I forgot to cast them together and I don't recall if I came to a conclusion about either.

The stand out rod to me was the Granger 7ft 4wt. I've yet to email the maker regarding exactly which Granger taper it was but I liked it more than the Garrison 201. The 201 at the gathering wasn't as smooth as the one I cast a few years ago. Could be it was the 201E taper or it might have simply been the line.

Jim Reams had some nice rods there. Specifically, he had two almost identical 3 wts. One was slightly faster, with maybe a lighter tip, I don't know it was hard to tell. The other felt slightly slower. The differences were slight but the first rod threw better loops while the second was more relaxing to cast.

I returned to the gathering for dinner. Chris had a great brisket going.

Regarding more current events, the 3wt is done. I think I can safely call it a 3 weight, although I don't think it was too wrong to label it 3/4.

I went over to Erik's house and cast the rod with his 3wt line. It cast fine. Not what I wanted when I designed it but not terrible. It is slightly heavy for a 3 and will fish a WF4 with little problem. A DT 4 is a little much though. I'm going to have to work on the finish though. It turned out poorly. I'll let it sit another week or two before I start doing that.

Erik is making rods at a very high level right now and the blanks he had sitting on the bench were incredible- nobody works nodes better.

I've started working on a new tip for the 3wt and have at the same time split the wood for the F.E. Thomas 3wt. I'll prep the wood for both rods until I'm ready for final planing. I'll plane and glue up the new tip and start work on the Payne 198 before finishing up the FE Thomas. The cane for the Payne 198 is already to go and has been simply sitting around most of the year.

10/18/08

The rod is in the drying box and has received a first coat of varnish. I may have to strip it all off and do it again. I dropped the tip in the tube which meant that I had to remove most of the varnish and then pour it back. That created tiny air bubbles which appear on the rod as tiny pin prick holes in the varnish.

I've decided to go back to one of my old styles of grips (see rod 7). I like look of the modified Powell type grip I've been using but have never been comfortable with it as I like to move my hand up and down the grip while fishing. Perhaps a combination of the two might work.

I marked the rod a 3/4, which I hate to do. I believe that a rod is designed to fish a single line weight and that is the line weight that should be used if you're going to stay true to the makers intent. Unfortunately, since I messed up on the tip, the rod really does feel like it's inbetween line weights. It casts a TT34 and feels a bit underlined and feels a bit over lined with a WF4. When I'm done I'll go over to Erik's and try his DT3 on it.

I've decided to make another tip and have asked Hiroshi to send me out another ferrule. I'll start prepping the cane for it as well as the cane for the FE Thomas 3wt. I've realized how far behind in my rod making I am this year, only making 2 rods, and have decided to make the Payne 198 instead of the FE Thomas 2pc. I'll make the Payne and go straight into the FE Thomas 3pc.

10/13/08

Well, I guess I didn't wait long enough on those tips. I finished planing the tips last week and glued up the sections on Saturday. The glue up was a joke. I put the binding cord knot in the wrong place and consequently ended up with a very twisted tip. I'm pleased to say though that I untwisted it without a hitch.

I scraped and sanded the rod today and as I stood there waving the tip back and forth, the action just didn't look right. It was faster than I expected and seemed more like a 4wt than a 3. I was a bit surprised at this so I mic'ed the entire rod. If anything, I thought the numbers would be on the low side but when I got to station 25, it was 0.10 larger than it should have been. Station 30 was the same and so it was for the entire tip. I had missed station 25 when I was setting up the forms. Before then really, I missed the station when I was calculating the form setting and didn't notice. My notes go from 0.059 to 0.715, when they should say .059, .0645, .0715. So I guess it's a 4wt now.

It's pretty frustrating. I was hoping to see how the 215 taper would translated to a 7ft length and now I'm going to have to build another rod to find out. Sure, I can build another tip but it will have to wait until February because I probably won't be able to get a duplicate ferrule until Hiroshi and co. are back in town.

The new bags are starting to take shape.

10/04/08

I got back from Asia last weekend. I'm still jet lagged and since I'm working on tips, I'm going to wait until my jet lag is over. I've been working on getting some new bags made. If all goes well they should be nice. MacKenzie Tartan with a hood and small pocket. I'm possibly going to get a golden trout embroidered on it. They'll have my name and rod size.

It's either going to be really cool or really ugly.

09/12/08

No rod making. I'm off to India and Hong Kong for two weeks. So much for having the rod done for the gathering........

09/03/08

Finished planning the butt, on to the tip.

09/02/08

Last weekend the Scottish Highland Gathering and Games were in town. Meat pies, bag pipes, men in skirts, the whole bit. I spent the morning wandering around the booths looking for some fabric patterned on the MacKenzie tartan. I couldn't find any but was able to order 4 yards, which will come straight from Scotland.

I should have enough bag material to last me a while. My last batch of material went to waste. I sent it to a famous rod supplier back east to have some custom bags made and he and his seamstress completely screwed up the order (even though I sent instructions in writing). The guy doesn't have email and tries to do everything by phone and obviously doesn't take notes. I got 15 bags that I couldn't use because they were all too small. I didn't get one of the two bags that were a must have or the complementary bag he was supposed to send to replace the missing "must have" bag.

Fortunately, I've got a new local source for bags, communication shouldn't be an issue I simply have to determine which style of bag I want and see if it can be made.

08/28/08

Wow. Twenty three days since my last entry. The rod should be done right now but its not. I spent about a week fishing and then my PC crashed. I've spent all my free time trying to fix it and of course the help desks at Apple and Microsoft simply made things worse. So I'm buying a new one and will be working on getting it up and running for the next couple of weeks....then its a week of fishing somewhere. I haven't yet decided where.

08/05/08

I've put a temporary hold on the bench. I've installed most of the drawers but I am about 3 short. My brother- in- law says he has the hardware I need. Instead of buying it, I'm going to pick it up at his place in a couple of weeks. So it's back to rod making.

I've started on the 3wt.. I planed the first strip tonight. I'm starting to develop tendonitis in my elbow. I thought it might be due to pushing down hard on the plane so I waxed the sole and boy does it fly down the form. This helped me figure out that I was gripping the plane to tightly. That and the fact that I bend my arm pretty deeply because I like to watch the sole of the plane as it glides down the form. I'm probably going to have to stop doing that.

Anyway, roughing went really quickly. Earlier in the year I was trying to help Jim Reams sell a rougher. No one bit so I made Jim an offer and to my surprise he accepted. Thanks, Jim.

I really lucked out, it's one of the older Bellinger bevellers and will rough a strip in one pass. Poof! I save myself a week of roughing and go straight to final planing.

07/25/08

Yesterday I glued up the second box and fit both in the bench today. I've placed a piece of Fin ply between the bench legs and box. This will hide the gap that would exist just above the bench foot and provide some contrast.

Now all I have to do is make the draws and a pair of cabinet doors.

I started working on the new rod today. I've split out the pieces and sanded the back side of the nodes. I'll let them soak until Sunday and then start working the nodes. The rod's definitely going to be 7ft, I've already cut it to size, whether it's a 3wt or 4wt I haven't decided.

07/21/08

Well, thanks to suffering heat exhaustion on the first day of my solo backpacking trip I'm home and in the shop. I 'm working on the bench again and glued up the frame for the first box today.

I've decided not to make the FE Thomas 3wt and instead try to tweak the 215 taper into a 7ft 4wt or 7ft 3wt. I think it should translate well. We'll see.

06/02/08

I'm back from a week long trip at Hot Creek Ranch. 10 days really and the rod performed beautifully. I need to lighten the butt up a tad but I'm pretty happy with the action.

The rod saw plenty of action with fish up to 20 inches. I need to clean it up and polish the varnish. The finish has a bunch of dips in it that need to be rubbed out.

I'm in the mood to "get back to my roots" and make a small rod so I'm going to start working on the FE Thomas 6'8" 3wt.

05/21/08

I'm in the home stretch. The rod's been dipped and the wraps varnished. I'll do a little sanding tonight and dip the last coat tonight. I spent all day Saturday playing with guide spacing. It's amazing how much a little change can effect how the rod performs. After trying Garrison spacing and several other spacings ranging from 4.25 inch first guide to 5.25, I finally settled on the spacing I use typically use starting at 4.375. It was the best compromise between in close, tight loops and distance.

Folks generally say that 1 guide per foot plus a stripping guide is standard but from what I've seen, Garrison, Payne, Dickerson and Howells used more. It makes me wonder where this "standard" came from.

05/16/08

The rod is sitting in the varnish tube for the second coat. The first coat had a few fish eyes in it. It's the first time that's happened. I've got a lot of triflow on my bench right now. It's what I use as a lubricant for sharpening blades. It must have some silicon or something in it. Hopefully I was able to sand off the affected parts and the next coat will go on without any problems.

05/15/08

The turning of the new grip went well. I test cast the rod last night. It's not exactly what I was hoping for, a little more powerful than what I was going for but for windy spring creeks and high country lakes, that's a plus. I'm not getting the loops I wanted and I think that is due to the fact that I missed the turn over point in the taper. The turnover point is at station 10 and that's still the turnover point on paper but station 15 came out .002 lighter than it was supposed to. It's the one station that was off more than .001 or .0005. Of all the stations to miss, it had to be that one.

The rod has this terrible ferrule click in it- really, really bad. Sure enough when I went to take the rod apart, the ferrule started coming off. A lot of people swear by pliobond so I've been trying it on my personal rods. I guess I don't have the technique down yet. The butt ferrule is staying put but the tip just came right off so I replaced the pliobond with golf shaft epoxy. I've never had problems with the epoxy.

05/13/08

Ouch. I turned the grip last night and once again it's out of round. I'll be glad when I get my new lathe up and running. I ended up turning the top of the grip too much, trying to get it into round and ended up with something I really didn't like so, I'm trying something new. I cut off the tip of the finished grip and I glued a new piece of glue to it. I'll turn it again tonight.

One interesting little tidbit is that when I cut the cork open, the glue on the inside was still wet. It was sitting for two days. I wonder how long it really takes to dry. It's supposed to be 95 degrees today, so I'll leave the grip outside and hope it's dry enough to turn tonight.

05/10/08

I cancelled a planned fishing trip to Yosemite today to spend some time in the shop and I'm glad I did. The rod's at a point where I can't work on it until Sunday or Monday night. The blanks are sanded, the ferrules prepped and the grip glued. I'd had some problems during the prepping stage with nodes and straightening and you can tell. It's not at the same level as my past few rods which is a bit disappointing. My friend Erik told me not to glue the rod up when he saw some of the finished and roughed strips. I don't have his experience so I wanted to see if it would really make a difference in the rod and from a craftsmanship standpoint- it does. The same flaws that were evident in the unfinished strips can be seen clearly in the rod. Ironically, the rod is not twisted.

Most guys would probably trash it but I'm excited to get together and see how it casts. I did a pretty good job about hitting the numbers. The tip is about .001 lighter than plan and the butt .001 heavier. Not dead on but close to it. That should make it ever so slightly faster than planned.

5/07/08

I'm back from Hong Kong and working in the shop again. I've also been tooling around my site a bit. Once every two years or so something goes wrong with the site; this prompts me to get out my list of admin. instructions and passwords to fix whatever the problem is. This generally leads to me coming across instructions on how to access the site statistics. The site stats tell me how many folks have been accessing the site, from where, how often, that sort of stuff. One of the stats gives me page views and it seems that this page, the rod blog, is pretty popular. Of course pretty popular is a relative term but the fact that anyone reads this blows my mind and is of course very flattering. Thank you for reading.

Most of the page views apparently come from Google searches but quite a few folks actually have the page book marked, which again is mind boggling. There are some strange stats as well; apparently I must be a subversive rod maker of some sort because China is the number 3 country in visits. Like I said, strange, maybe they think I'm trying to overthrow the government or something. I did go to UC Berkeley after all......Free Tibet! Actually, I'm more of a Nepalese kind of guy. It's my favorite food.

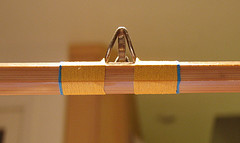

Anyway, I'm back to rod making. I glued up last night. My gluing sessions are a pretty relaxed affair and it usually takes me 4 or 5 hours. I use Urac 185 and store it in the refrigerator. I usually pull the glue out and give it a couple of hours to get to room temperature before I use it. During this time I take some time to clean up the shop and get everything ready. The rod binder I'm currently using is screwed to the back of my router table so I roll the router table out and clean the binder of any dry glue.

I usually wipe the binder down after gluing but I don't go crazy cleaning it. There's usually some glue left over that simply flakes off when it dries. Urac can be mixed with or without the walnut flour the company provides. I still use the walnut flour. It's a little thick and adds a few extra thousands of an inch to the my rods but I think I've learned to compensate for that- at least somewhat. I had planned to mix the glue without the walnut flour for this rod but I've been to busy to pick up the ammonium chloride needed.

The last couple of rods I've mixed with about 3/4th of the required flour and they came out ok. I'm still getting glue lines which can be due to my planing, the glue thickness or the tightness of the binder. I haven't quite figured it out and different folks have different opinion. I don't get glue lines when I use my 4 string binder but I haven't been able to use that without my rods turning into a twisted mess. I don't see well enough to remove twists before the glue dries, so if I can avoid it, I do. The rod last night developed a twist when my binder jammed with glue. Hopefully, I got it out.

After cleaning the binder and cleaning up the shop a bit, I'll lay down some butcher paper and then some wax paper on my bench. The butcher paper is for sizing the rod and providing a clean surface. The wax paper helps with the glue. I then pull out everything else I'll need, the scale, a spoon, a couple of cups, stuff like that. Measuring and mixing the glue is pretty quick and I use the 100:13 glue/flour ratio suggested by the company that produces the stuff. Last night I mixed something like 126:17 which comes out to be about the same ratio.

The 215 is longer than any other rod I've made. It's 8ft but a two piece so each section is slightly over 4 feet long and I wasn't quite prepared for that. I got by but my gluing could have gone smoother. The sections seemed to keep going and going. My shop isn't really set up for rods that big so I'm not really sure what I'm going to do about finishing the rod. It's two big to fit in my dipping apparatus.

Tomorrow I'll sand using 400 grit sand paper. I usually go down to 600 but I read that the grain in wood actually stands out more if you don't go as fine. We'll see if it's that way with cane. If the blanks are straight and without twists, I'll probably be able to add the tip top and maybe even glue some cork on for the grip. Things will slow down then as I set up my new lathe before turning the grip.

4/18/08

I've been spending my time working on the bench. It's starting to come together but is taking longer than I expected. The fir I'm using is pretty soft and that's causing all sorts of problems. Next time I'll use something harder for the feet and pins. The fir tears out a lot.

It's starting to look like a bench though.

04/07/08

Still trying to do a bunch of stuff at once. Saturday I found some really good spaulted amboyna burl and spent the afternoon cutting it up into reel seat blanks. I've done some testing with the other amboyna blanks and the blanks seem to dry too quickly inside the house. They're checking like crazy. The blanks in the garage seem to be doing ok. So I'll dry the wood out there.

This weekend I completed compiling the wood for my bench. It's going to a sled foot bench of mortise and tenon construction using clear Pine and Walnut for the frame. I haven't decided on whether to use a double wedged tenon or pins. I'm leaning toward pins as I can use walnut pins on the pine to provide some contrast. Walnut is too expensive to make the entire base from but I wanted some nice contrast so the two walnut 4x4s will make up the side aprons or shoulders and the pine will be the legs, feet and stretchers or side boards. The top is a 1 1/2 inch beech counter top I picked up at Ikea. It's a little thinner than I might like but it saves me from laminating and planing the top myself. There will be a box cabinet in the center which will give the bench added rigidity and help support the relatively thin top.

The box will have walnut pulls. I haven't quite worked out the other particulars of the box as I haven't quite decided what all I need to store. I need storage for all the bits and accessories that came with the lathe, so one shallow and medium drawer should do. I should probably store my grinder there since it will be needed. That leaves me with a lot to work with. I need storage for me wrapping jig. In fact now that I think of it, the bench might also make a good wrapping station. Maybe I could install a drawer from my wrapper that I could also wrap from. That would be handy.

I've still got a long way to go before I have to make decisions about the box. I've cut the tenons on the legs, with one extra to test with and have started cutting the mortises. I cut the mortises with a drill press and then chisel out the excess.

On a rod making note. I knocked out spline 4 for the 215.

04/03/08

This week I've been doing various and sundry things in the shop. Not really concentrating on a single task. My bench making has been put on hold until this weekend. I've picked a nice beech bench top and some walnut for the upper braces. I've got a good bit of oak and birch ply I can use for the cabinet part but I'm still shy a pair of legs. I wanted to make the legs out of something light in color and was thinking about picking up some pine 4x4s but the stuff I've been able to find thus far has been crap. The stuff at home depot was cracked, wet and knotted. I don't know how they sell the stuff. The quality of available pine has really gone down hill in the last 10 years.

I cut 4 blanks out of the amboyna burl. I've got two sitting in the garage and 2 sitting inside. I want to see how they dry. The ones inside are starting to crack. I need to find some PEG or Polyethylene Glycol to help stop the cracking. Polyethylene Glycol is NOT the stuff in antifreeze. I think that's Ethylene Glycol and those that watch New Detectives know it's highly poisonous. PEG on the other hand isn't. An interesting, if old, document on using PEG in woodwork can be seen here: How PEG Helps The Hobbyist Who Works With Wood.

I got a spline or two done on the 215 rod. I'm really having trouble with my angles for some reason and the splines seem to have relaxed and are no longer straight. Erik says I shouldn't glue them up but I don't have his experience. I need to see what's going to happen when I do.

The rod was already headed down the wrong path as I planed a spline top to bottom instead of the other way around. The spline is noticeably stiffer and the nodes won't be in the right place in the finished rod. I'm using Garrison's spacing so it shouldn't really be noticeable. It's my rod so, no big deal, it'll fish but simply not be the "sum of all I've learned so far" that I was hoping for. I wanted to start hollow building this year but I think I've still got work to do on the basics.

I've been perusing woodworking magazines for bench designs and one magazine had an article that got me thinking about shop safety. I have fire boxes in the shop installed for storing volatile chemicals but I've never really used them properly. After reading the article, I decided to take my shop safety a little bit more seriously and went through the box to rearrange and structure things. It's amazing the amount of stuff you accumulate and forget about. I found nearly 20 quarts of wood finish products. Most of which I forgot I owned. That doesn't include the spay varnishes, epoxies, glues and thinners. I even had some navel jelly and pitch from my sword collecting days.

The final finishing tally was something like this:

3/30/08

Wow, the last month has gone fast. I've been working on my next rod, the "215", so called for the high point of the tip on the Garrison stress curve. I'm actually on final planning but have put that on hold because I recently picked up a new lathe.

It's a long story but I decided to get a lathe, looked on ebay and lo and behold, the perfect lathe was offered for sale the next day. I shot the seller an email and to my surprise it was Chris Raine selling the lathe. I bid and won and then drove up to Dunsmuir to pick it up. Now I'm working on making a new bench to carry the thing. I've got the bench design, now I'm working on acquiring all the wood.

In addition, the local Rockler had a special sale on burl. I picked up enough Amboyna burl to make about 30 seats at a fraction of the cost of an REC Amboyna insert. It's pretty cool stuff and I'm excited to start working on the lathe but first, I need to clean the garage up and make the bench.

Last night I had the pleasure of eating dinner with my friend Erik, as well as Yukihiro Yoshida, Shinichi Tsuchiya and Hiroshi Kono. Yukihiro is the rod maker I met at the show over the weekend and he was joined by Shinichi, who was here to sell his handcrafted nets, and Hiroshi who serves as their rep. in the US.

We had a great time talking rods and fly fishing, casting rods and eating. Yoshida- San's approach to rod making is very interesting. He didn't have anyone to show him how to make rods when he started, no Garrison book or other rod makers. He came up with his own techniques based on traditional Japanese methods of craftsmanship. He is extremely particular regarding the cane he uses and uses Madake because, among other reasons, he can cut it himself. When asked if he'd like to make rods out of Tonkin he replied, only if he could cut it himself.

And just as one would expect when a group of rod makers get together, the word "secret" came up quite few times.

On a more personal note, I've decided to make the 2pc 8ft 4wt 215 rod first, even though I prepped the wood for the 3pc rods late last year. I'm eager to try these new ferrules so I started splitting cane for the new rod tonight. Hopefully I can have it finished by the time Vita and I go to Mammoth. It should make a good rod to fish Hot Creek Ranch with.

2/24/08

Yesterday I picked up some new ferrules from the Japanese guys at the show. I'm pretty excited to use them so I've revaluated my rod making list for this year. Currently, I have enough ferrules for 5 3piece rods and 3 two piece rods. The ferrules I picked up were extra short super swiss style so I've decided to make a 2pc version of the rod I'm calling the 215 instead of a 3pc.

The 215 is a taper I developed based on the my experience with the rods Jerry Foster had at last years great western. I've lighted the rod one line weight so that it will accept the size 13 ferrule I picked up. In addition, I'll make the convex rod and a Payne 198, as well as an FE Thomas 6'8" 2pc and a Garrison 201. 2/23/08 The Fly Fishing Show was in town today. Each year there seem to be more and more cane rod builders. In addition to the usual suspects, there were three new rod makers attending. Doug Kulick was there. If memory serves he attends every other year. Another fellow was there whose name I don't recall and there was a fellow from Japan named YukihiroYoshida. His rods were interesting because they were made out of a Japanese cane called Madake. The power fibers in Madake seem to be smaller and more concentrated than in Tonkin. The cane looked as if it would be good for hollow building. I cast one of his rods, a 7'6" 4wt. it was different than I expected. I expected a slower rod with a more full action. The rod was sort of medium fast and threw a nice line. 02/10/08 C'est fini! I did the varnish on the grip bit but I can't say I really like it. The foot print is too big. The rod will stay in the drying cabinet for a few days and then I'll take it out and cast it again. Hopefully the weight of the varnish hasn't taken anything way from the way it cast.

02/05/08 I've put the last coat of varnish on the wraps for the Payne 97. I'll give it a couple of days to dry and then dip the entire rod one more time. No sooner have I finished making the Payne, I've been asked to do another rod. A 3wt this time. It'll be my first. I've been wanting to make the FE Thomas 6'8" rod so this will be a good excuse. It's got to be a 3pc so I'll very slightly modify the rod. Before that though I have some other rods to finish. I've got enough cane prepped and roughed for 2 8ft 3pc rods. One will be a Convex rod based on a Vince Marinaro taper and reduced a couple light weights to a 4wt and the second a rod based on my experience testing Jerry Fosters rod. I should be able to finish both by opening day and either should work well for the week I'm spending on Hot Creek in May. Then I'll finally get to Gina's rod, which I've now decided will be a Garrison 201. So it looks like my 2008 is already filled up with rod to do. My journey into hollow building will have to wait another year. 1/31/08 I canít believe Iím going into my 4th year of rod making. Iím pleased to say that my craftsman ship is getting better. I donít know if I can say Iím building better rods than 4 years ago but Iím confident that the rods will have fewer problems and better cane work. Iím not working a blinding production cycling, maybe 4 or 5 rods a year- of which Iíve sold 4 and given away 3. That means Iíve got 10 hanging around the house somewhere and for the life of me, I can only picture about half of those. The early rods had ferrule problems but that seems to be a thing of the past. Iím happy to say that Iíve had a chance to check out the rods I sold 2 years ago and theyíre holding up well. I was even surprised by how well one of them cast as I remember not liking it much. Iíve had problems dying the rods with potassium permanganate and those rods will have to be re-finished. Iíve started using a new dye and hopefully that will hold up. Iím a little nervous that it wonít but weíll see. For some reason, this year was a year of challenges but that resulted in great learning. Iím not as confident with my rods this year as I could be. I chalk that up to the challenges Iíve faced and the higher standards and expectations of myself. Of the rods Iíve made, Iím particularly happy the looks of rods 14 and 15. Not necessarily the cosmetics but the over all color scheme. Both were wrapped with orange silk but you wouldnít know it looking at the pictures. Iíve settled on a grip style but Iím far from being able to reproduce it consistently. Iíve particularly liked the Payne 197, 97 and 200 tapers. The last Payne 97, the one Iím working on now (rod 17) was a super casting rod before I put the guides on. Letís hope the varnish hasnít deadened the action any. This year Iíll try to work on cosmetics. My cosmetics are weak and itís time I brought them up a bit. Iím still having a problem with glue lines. The seams are even but there are still lines. My buddy Erik says itís my planning and Iím sure thatís part of it but I still feel like eliminating the walnut flour and thinning my glue will help. Having a rod making buddy in town has been a great help. There are least 7 rod makers within 20 miles of my house but we donít really know each other. By the end of February Iíll have all of my commitment rods out of the shop and Iíll be able to try some new things. Itís hard to try new ideas on rods youíre making for others because you never know how itís going to come out. Iíll also go back to making short rods. I feel like all Iíve been making is long rods and while thatís not true, the next two rods up are 8ft rods. After that, maybe Iíll get around to making a rod for my friend Gina. If the last two rods were hard, the rod for Gina seems to be the one that never gets built.

1/30/08 Since my last post Iíve been wrapping and finishing and wrapping and finishing. Rod 6 is re-wrapped and the wraps are waiting for a final coat of varnish. I havenít decided yet if Iím going to put an over coat of varnish on it or no. My early rods were finished with tung oil. I really like the look and they seem to be holding up and I often think about going back to tung oil but Iíve since learned that tung oil isnít a very good vapor barrier. I donít think that will be a problem so long as the rods isnít soaked in water for long periods. Iíve heard of rods being lost and later found at the bottom of a large pool. The rods have come out fine. I donít think that would be the case with a tung oil finish. Maybe I should try to hand wipe a tung oil/epifanes mixture. Rod number 17 is wrapped and on itís 4th coat of wrap finish. Iíll be so relieved if I can get this rod finished without any more mishaps.

01/12/08

I've done quite a bit of work this week. I've had rods 5 and 6 back for some time in order to fix the ferrules. I've re-glued the ferrules and they should be good to go in about 2 weeks. I've rewrapped rod # 6. It was the rod that I tried my flex coat experiment on and I never did like the way it looked.

Before:

After:

I've also decided to finish up the 97. I dipped it in varnish today and will again tomorrow and then I probably won't get to it for another two weeks. I'm off to Miami for a week and when I get back it will be back to rods 5 and 6 before finishing the 97.

01/07/08

It's hard working in winter. The shop is not heated so that means I have to tackle gluing and dipping on the weekends during mid day when it's warmest. So, I'm starting to work on some other rods that I have lying around. I have two that need re-gluing of ferrules and new wraps. These I can do inside.

I've turned the handle on the Payne 97. It's a tad thin and may look a little strange but it feels good. I've been tending toward smaller grips and have finally come upon the grip that I like. By smaller I really mean thinner. The grips are full size but the Payne 97 is a delicate rod and should be cast that way, not cast like an 8ft 7wt and therefore doesn't need a huge hammer grip.

|

|

|

|

|

I

cast longer than planned and opted to fish the City Park rather than

drive elsewhere. I got about 1.5 hours of fishing done I think and

though not fast action, the fishing was consistent with a fish coming

out over every other pocket or so.

I

cast longer than planned and opted to fish the City Park rather than

drive elsewhere. I got about 1.5 hours of fishing done I think and

though not fast action, the fishing was consistent with a fish coming

out over every other pocket or so.